Assembling the ACP Panel

This is a very crowded panel and there will be little use for all the potentiometers in the final sim. The first thing I noticed was that the recesses in the IBL panel for the potentiometer nuts were not large enough and the panel could not be assembled with the pots in place. I decided that it was too risky to open up the counterbores in the panel so I turned down the nuts. Although this removed the hexagon there was no problem in tightening them with a pair of pliers.

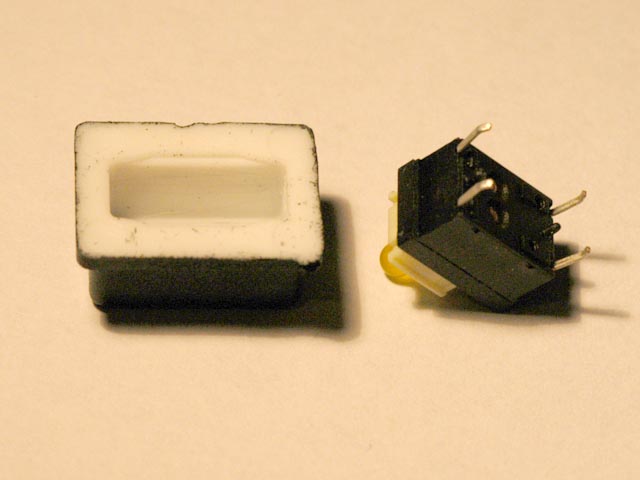

There was also a bag of knobs for the pots but these were too tight on the spindle and even if they could be fitted they could not be removed without a risk of damage. I need to find or make some better ones. In the picture below the one on the right is supplied, the one on the left is from my scrap box, better but not yet right.

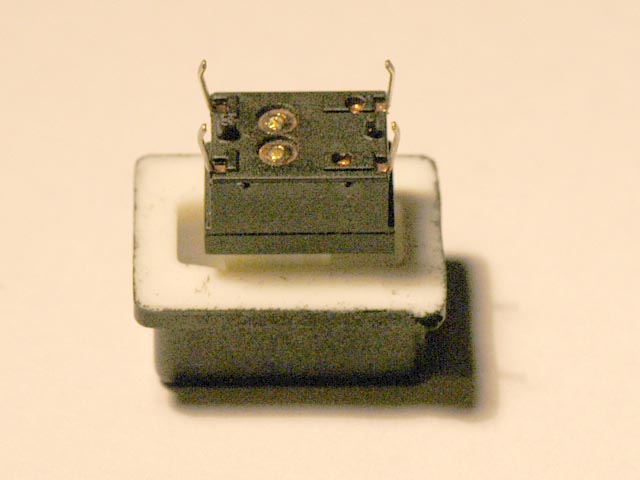

Accuracy is paramount with this assembly, the switches must enter the recesses in the push buttons in the free state, too close and it starts to press the switch, not far enough and the push button tends to get out of line. It should also be noted that the switches are aymmetric and need to be set slightly off centre from the button to ensure that the switch plunger is central on the button.

With the assistance of another cockpit builder down the road I was able to sort out the plan for the push switches, however the mountings did not seem to relate to the panels so they will need modification to fit. They will need packing off the panel to get the height right and a method of attaching them must be worked out.

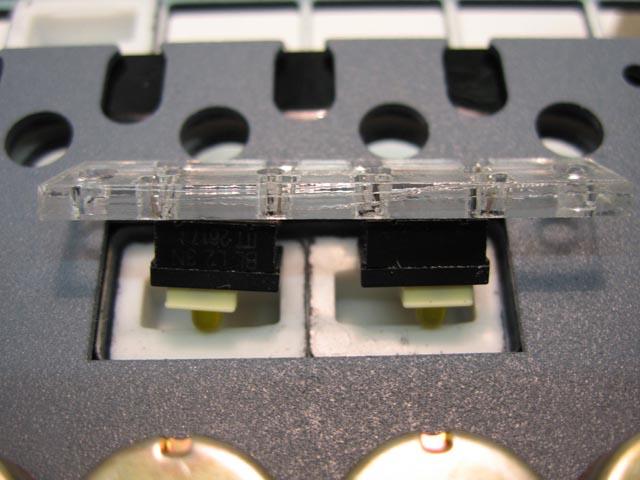

After a few dummy runs I decided that the switch mounting panels were not really suitable, they appeared to have been made for a different standard of panel as they did not logically fit the metal backer. Also the laser cutter seems to have run amok and the holes were badly cut. I decided to remake these panels. Discussions later with FDS confirmed that I had been sent the wrong panels and that ones had not yet been made for this standard of IBL part so I would have had to make them anyway.

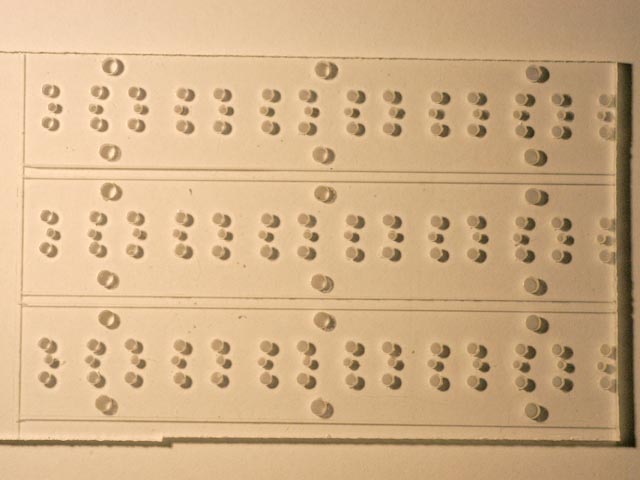

These are my new panels ready to be cut out. I made a spare while I was at it in case I messed one up later

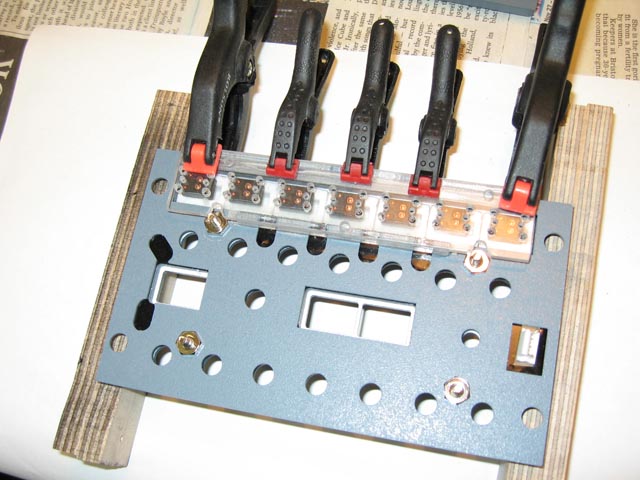

The height of the switch mountings above the backplate has to be very accurate; if it is too high the switches come out of the recess in the buttons and the buttons get misaligned. If it is too low the switch action is wrong. I found that I needed to pack the switch 0.175" above the backplates. I made accurate packing strips, super-glued these to the switch mountings, cleaned the paint off the backplates and super-glued the assemblies in place. Once the IBL is separated from the backplate the buttons and switches can be removed for wiring later.

The next major issue was the potentiometers (15 of them). There is not enough room to fit them in the panels. In the sim they are no needed anyway as the software does not have the functions. One or two might come in handy however. If the potentiometers cannot be used there is the issue of mounting the knobs which will be needed for "eye-candy".

My final solution was to dismantle the pots where there was insufficient clearance to fit the full unit. This still left the spindles rotating smoothly and they can be firmly mounted to the panel for the fitting of the knobs. It seemed a bit brutal hacking up the pots but it is probably the best solution. I was able to fit four complete pots so they can be used if required later.

A very tight fit!

The finished panel, just needs knobs and wiring.